What Is A Sealing Flange? A Detailed Explanation

A flange is a way of connecting two pipes or metal surfaces, and SealingFlange refers to connecting those surfaces without creating a gap. In the

commercial and industrial worlds, we make use of many flange surfaces. It could

be connecting metallic pipelines that carry fluids, or the two outer covers of

vehicle engines, and components of pressure machines. No matter what is it, the

crucial fact is creating a seal or leak-proof connecting points. For example,

can we allow the pressure inside a vehicle engine leak? Or, gas-carrying

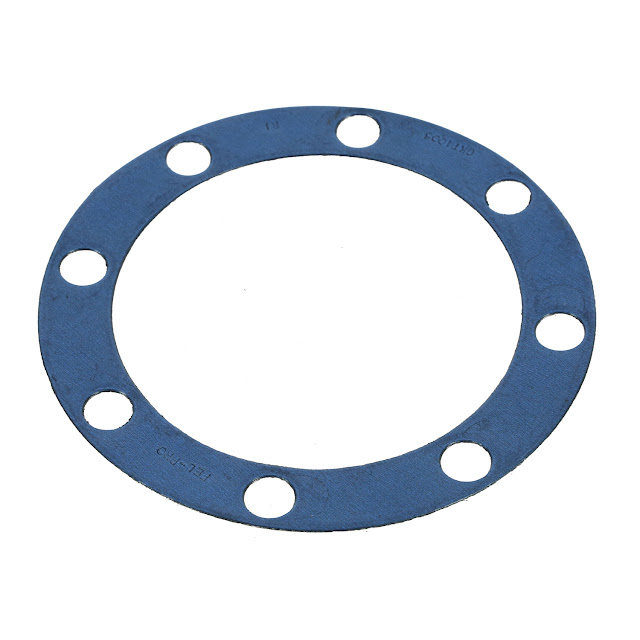

pipelines leak at the connecting points? Sealing Flange is not possible without flange sealing materials such as a

flange gasket.

Here, we use methods to fill the gaps or irregularities that may exist

between two connecting flange surfaces. Why would a passage occur between two

connecting metal surfaces? Well, metallic surfaces may be polished or smooth

ones, but when connecting those; we need a material that acts as a filler in

between those. Let's say you connect two metallic pipes, and the edges of those

are smooth. Still, can you expect those two pipes to result in a perfect seal

at the connecting point? No, and that is why technicians and engineers focus on

Sealing Flange to a greater extent today.

The need for Sealing Flange becomes a must-have at times when high-pressure

and fluids involved. What are the commercial and industrial applications where

both these elements present? Well, how about gas-carrying pipelines in a gas

plant? Here, petroleum gas is fluid, and it moves under high-pressure. And,

this means you should connect those pipelines in such a way that no gas can

escape, or the connecting points won't fail under pressure. We can make those

joints secure ones by using nuts and bolts, but it doesn't make those

connecting joints are leak-proof ones. Sealing Flange is the method to use in

this case. Gas plant fires have caused disasters in the past, and we can't let

such accidents happen again.

Other applications such as connecting the two metallic covers of vehicle

engines also need perfect sealing. If the pressure inside of those engines

leak; it will result in power loss or even fires. Again, the same challenge

comes. The outer covers of those vehicle engines are metallic ones; their

surfaces may be smooth ones, but 100% sealing won't happen without Sealing

Flange. To fill the irregularities, we need a soft or malleable material piece,

but it withstands harsh conditions such as high-temperature. And, this means we

don't use ordinary rubber gasket for this Sealing Flange purpose.

Why can't we weld those pipes or engine covers, why do we flange those?

Well, the reason is pretty understandable. If you weld those engine covers; in

case of engine repair; how would you open it? The same story applies to

pipelines as well. It is safe to say that flanging those metallic surfaces let

you conduct inspection and maintenance tasks as well. Using nuts and bolts and

Sealing Flange is the methods used since the old days for this crucial

purpose. Depending on your application, make sure you choose the right Sealing

Flange method. Most of the time, a material piece acts as the filling element.

At WR, we supply quality products to fulfil this requirement.

Comments

Post a Comment